Performance

We would like to take the time to lay down the facts of highly-modified S&S 6.7 Cummins injectors. Some may think that 250% over-stock fuel flow is the limitation of the 6.7 Cummins injector body. While we can’t speak for our competition, this is not true for S&S Diesel Motorsport 6.7 Cummins fuel injectors.

There are a few things to consider when using the % over stock categorization that the aftermarket has adopted. The % over number is calculated by flowing the nozzles by themselves, not the complete injector. For this reason, we would prefer to categorize our injectors by what their exact flow numbers are, but this is difficult without using a standard rail pressure and energizing time. For the time being, we also categorize our injectors on nozzle flow, yet we include a detailed flow sheet that shows the output of each complete injector.

We test our nozzles with the needle out, using the industry-standard Viscor SAE-J967 calibration fluid at 100 bar with a constant temperature of 40 degrees Celsius. On our test equipment, a stock 6.7 nozzle flows 1,200 cc/min and our largest 6.7 nozzle flows 6,600 cc/min, which we classify as a 450% over nozzle per the following equation: (6,600 – 1,200)/1,200 = 4.5 or 450%.

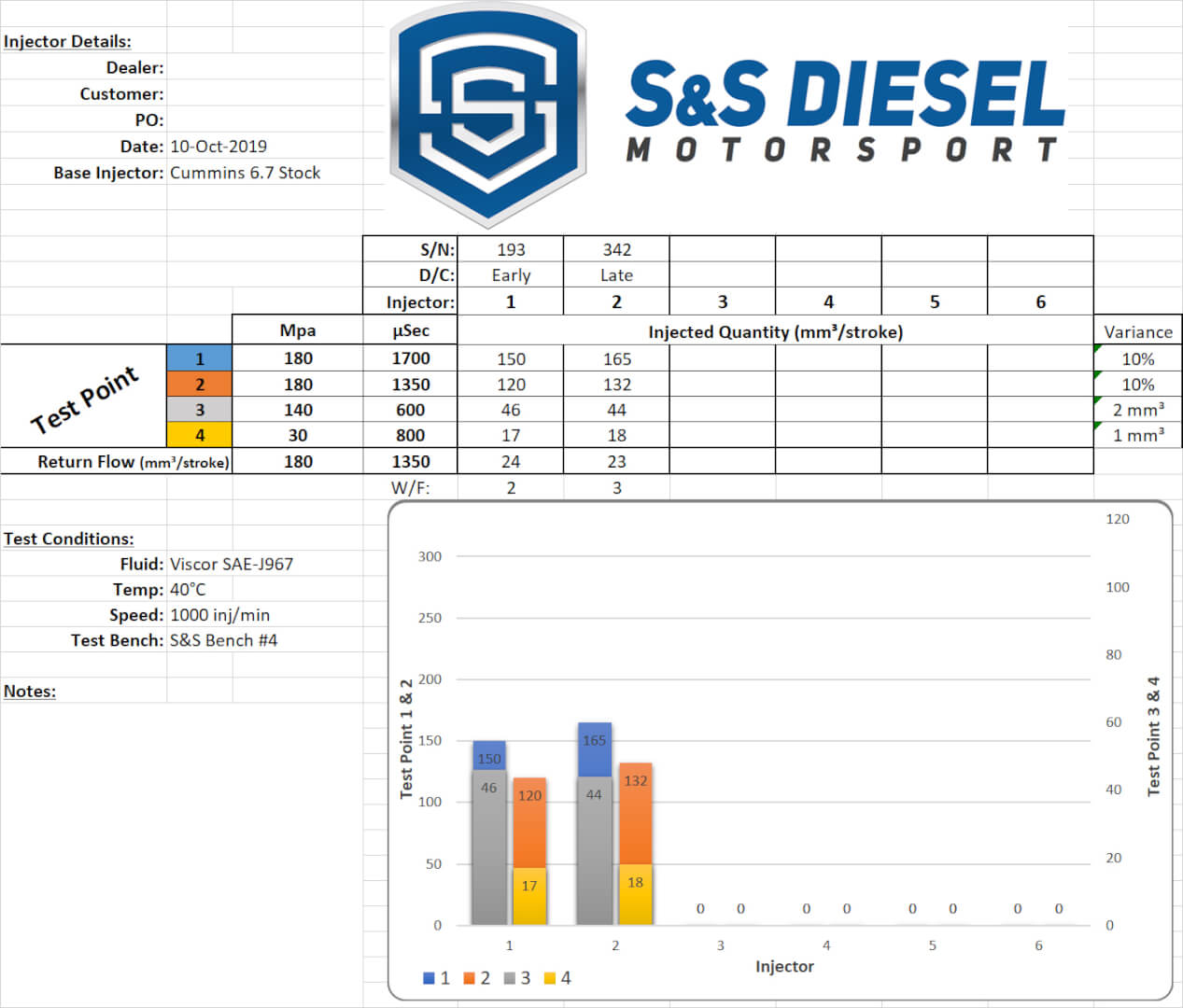

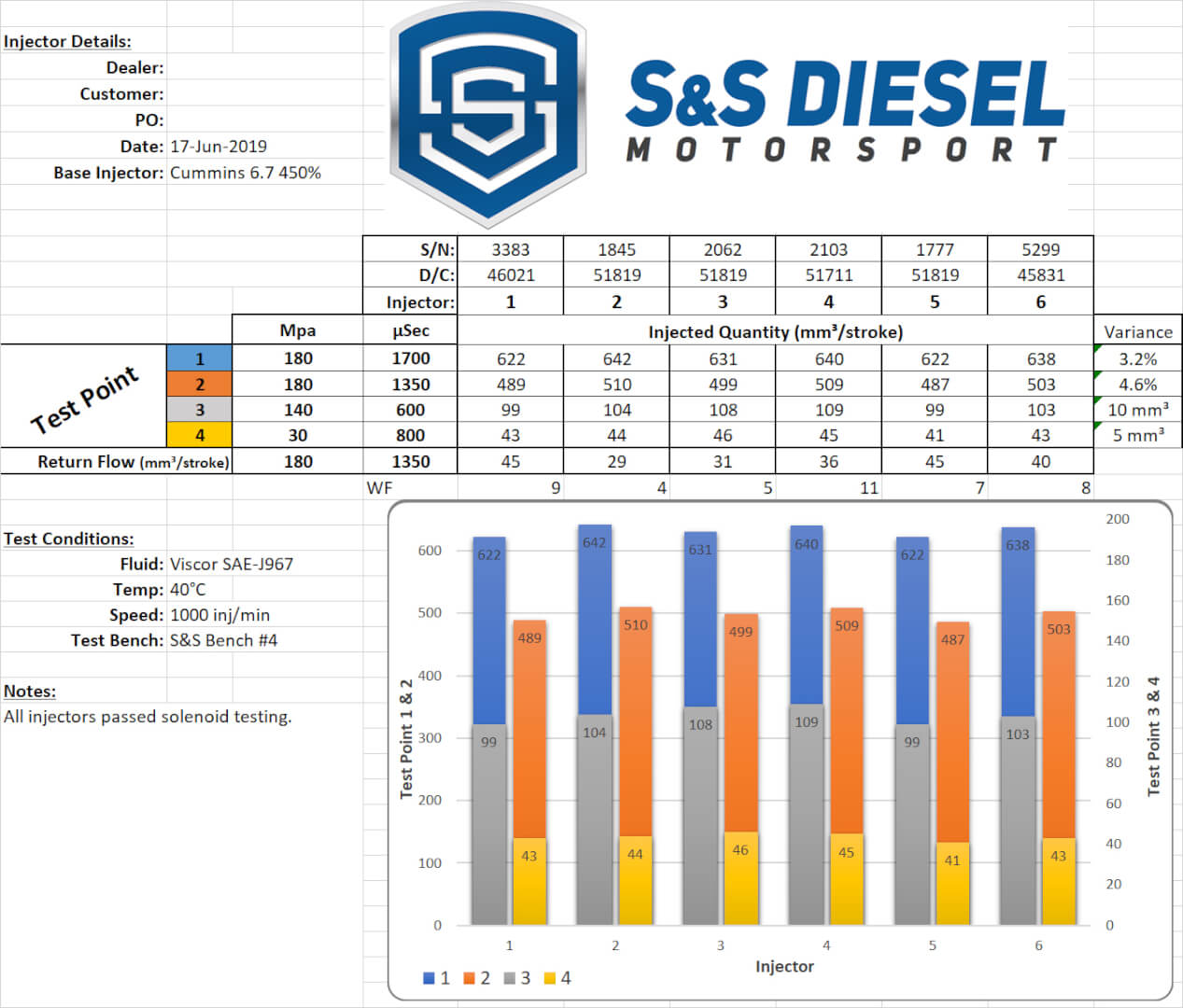

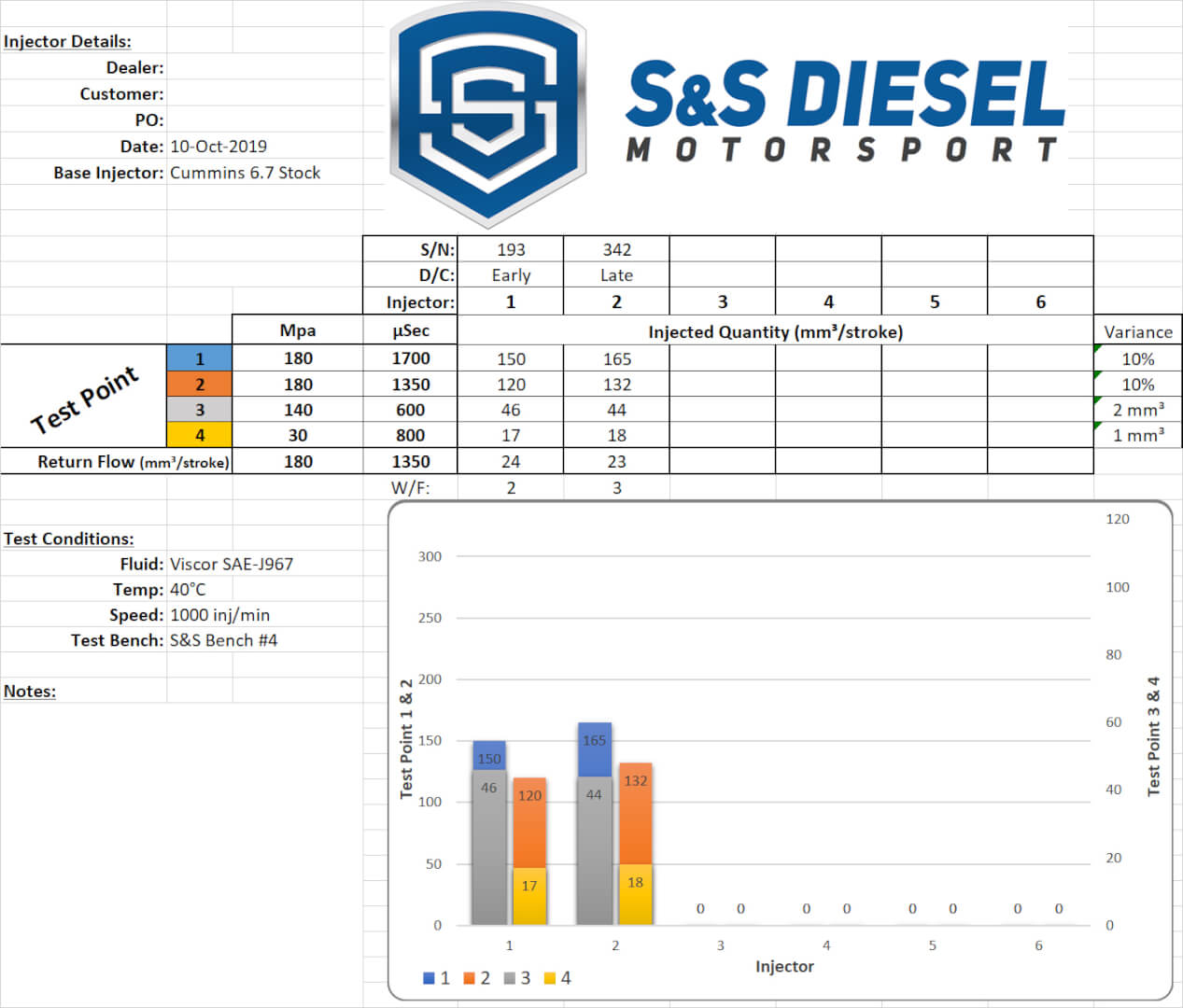

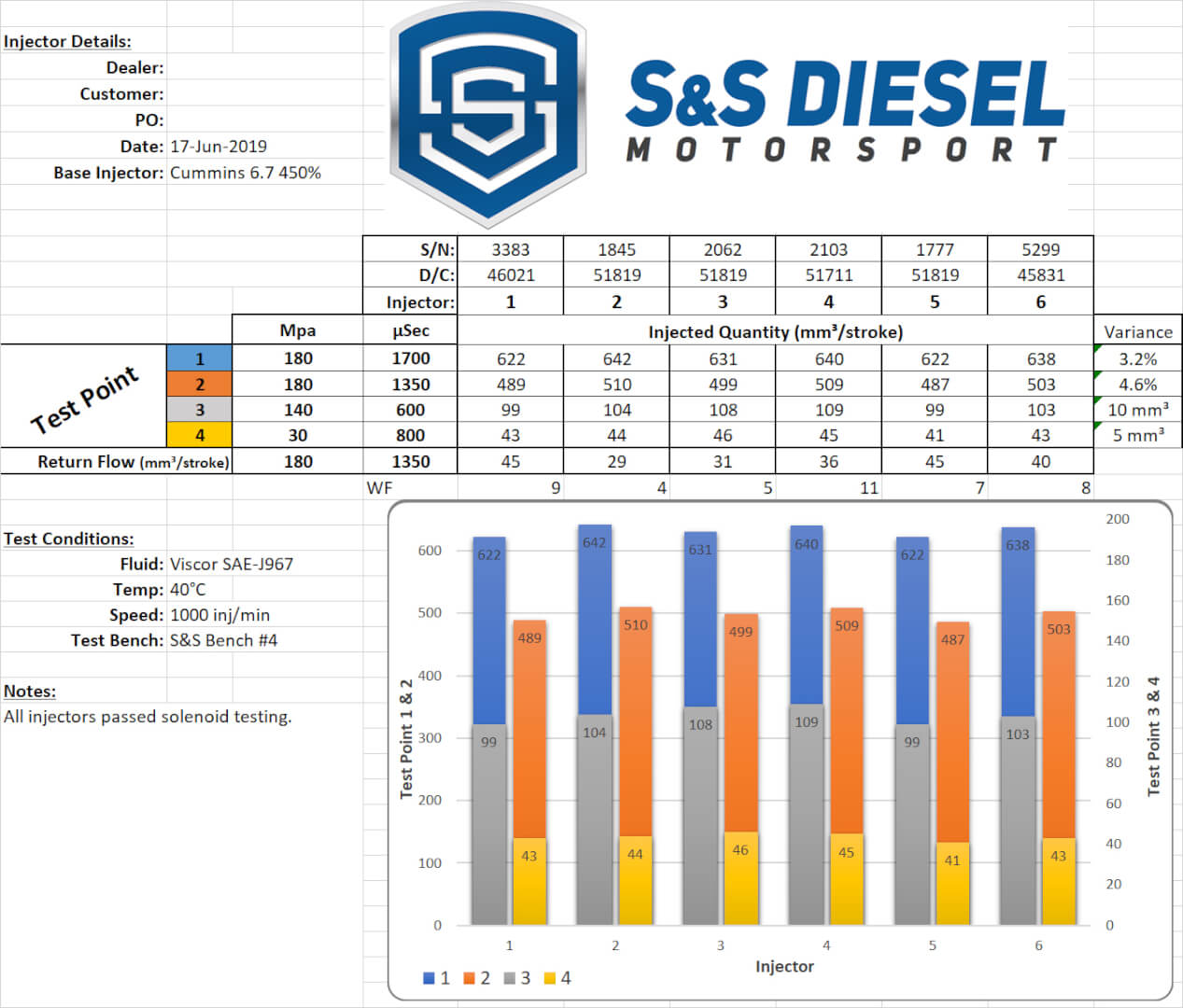

Since we are a company founded by OE engineers, we prefer to use data to prove our point, rather than expecting the diesel industry to blindly take our word for it. So, let’s compare the actual fuel delivery per stroke of stock 6.7 Cummins injectors and a set of our 6.7 Cummins injectors with 6,600 cc/min nozzles, more commonly known as 450% over injectors. Late-model (‘13-‘18) stock 6.7 Cummins injectors flow slightly more than the early-model (‘07-‘12) 6.7 injectors, so we’ll use both for our test.

OE Bosch 6.7 Cummins Injectors

S&S 6.7 Cummins 450% Injectors

We can compare output in mm3/stroke at 1,700 µSec for all injectors. Output of the early 6.7 Cummins injector is 150 mm3/stroke, output of the late 6.7 Cummins injector is 165 mm3/stroke, and the average output of our 450% set is 632.5 mm3/stroke. Below are calculations for the increase in fuel delivery per stroke of both variants of stock 6.7 Cummins injectors:

Increase from Early 6.7 Injector – (632.5-150)/150 = 3.22 or 322%

Increase from Late 6.7 Injector – (632.5-165)/165 = 2.83 or 283%

When comparing the stock 6.7 injectors to our 6.7 injectors with 450% over-stock nozzles, the nozzle flow increase and actual fuel delivery increase are not the same, yet a 250% increase in actual fuel delivery is NOT our limit. Moreover, a 322% increase in fuel delivery through the complete injector is what our 6.7 Cummins injectors with 6,600 cc/min nozzles and accompanying body modifications can do.

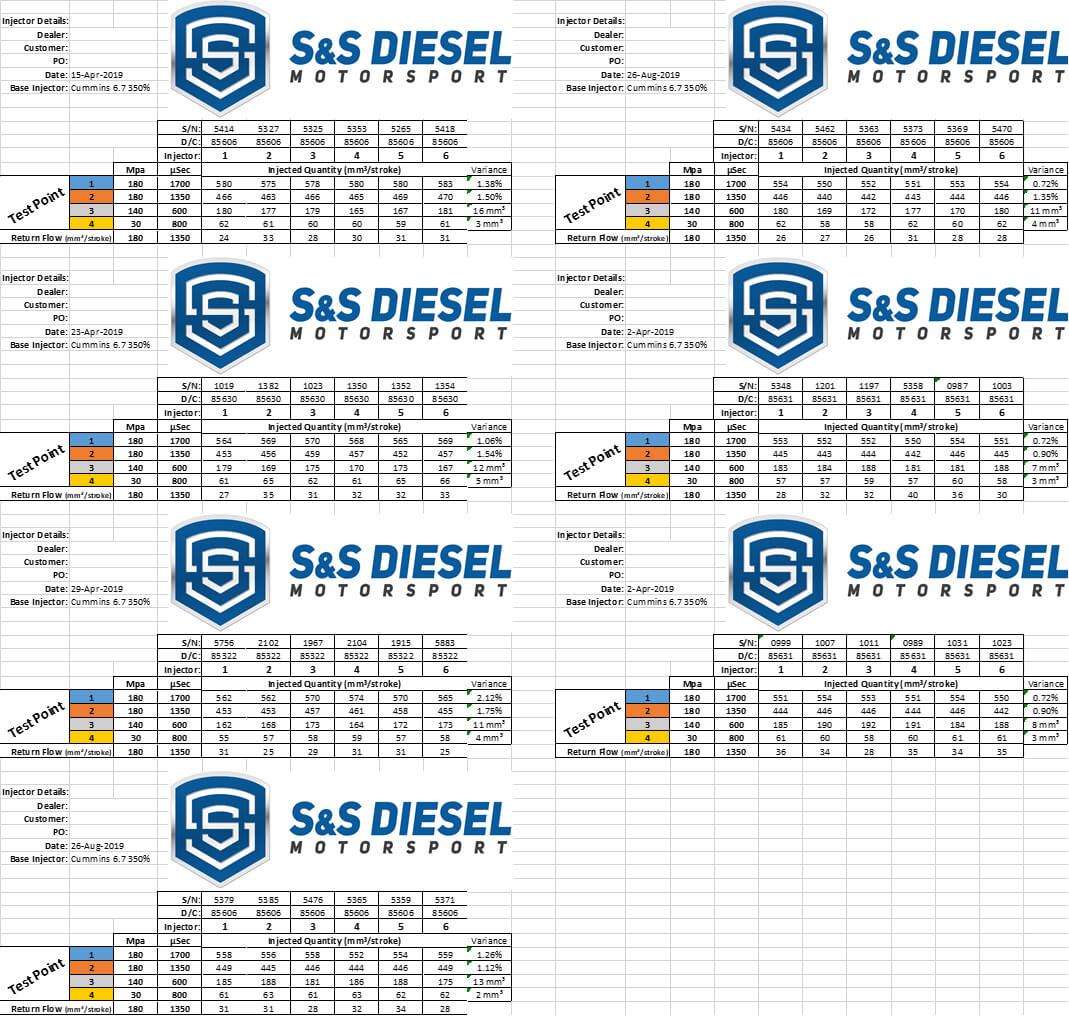

Consistency

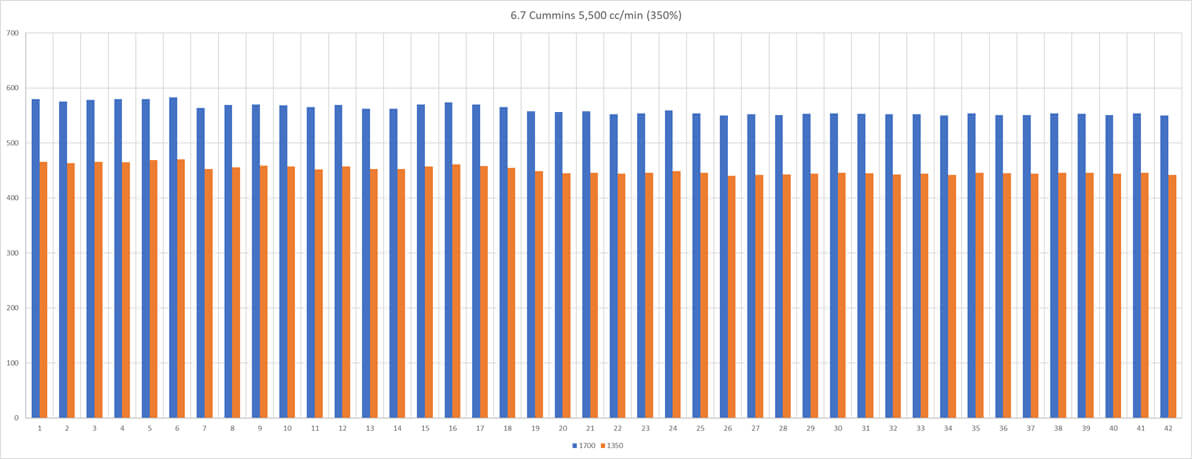

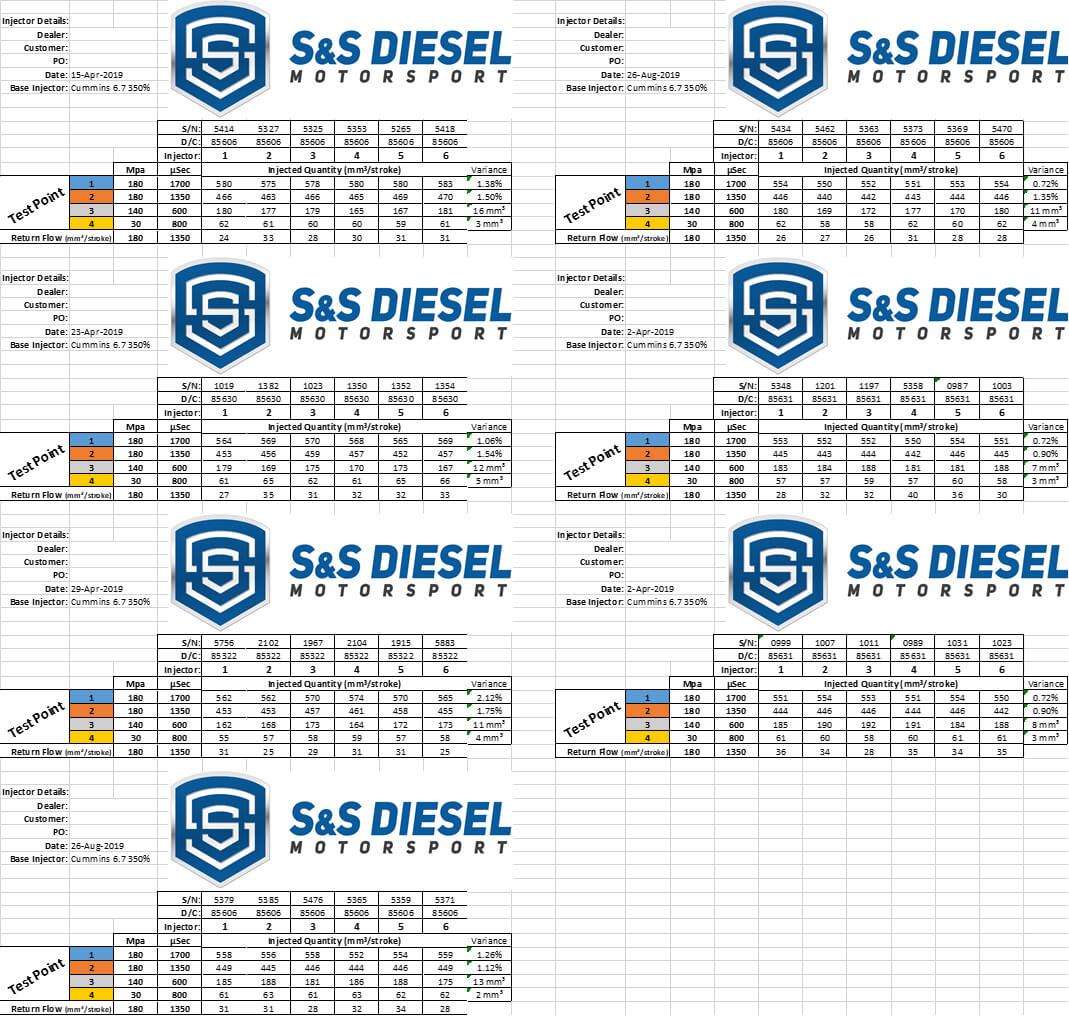

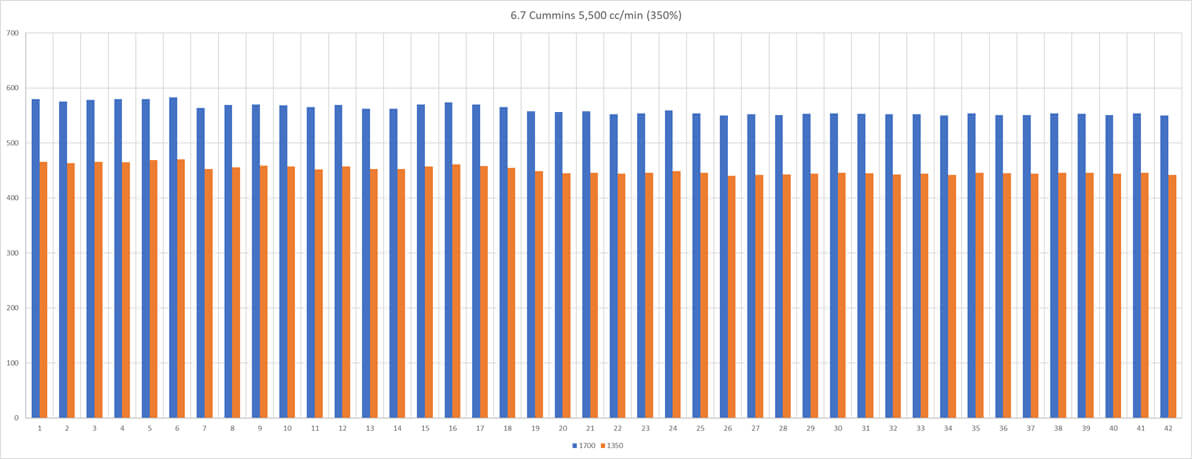

Some people may be under the impression that consistency is impossible for highly-modified aftermarket injectors. This is also not true for S&S Diesel Motorsport injectors. Below are datasheets for 42 different 2,000+ horsepower capable injectors with no more than 2.12% variance per set, and 5.9% total variance across all 42 injectors.

7 Tightly Balanced Sets of S&S 6.7 Cummins 350% Injectors

42 S&S 6.7 Cummins 350% Injectors with 5.9% Total Variance

The Bosch factory spec at the same rated point on stock injectors is 8% total variance. Not only are S&S Diesel Motorsport 6.7 Cummins injectors capable of delivering roughly 322% more fuel than stock injectors, they are balanced to tighter tolerances than stock injectors.